A Q&A WITH CAP LOGISTICS

For the most part, pieces and parts for businesses in the heavy industries is not manufactured or produced in place. Most of what is used by the mining, oil and gas, or the equipment industry, for example, must be moved around the country. Throughout the week, business runs as usual, but there are instances where companies are forced to make quick decisions that involve moving these pieces and parts for an operation around the country or the world quickly.

A smaller transportation company called CAP Logistics does just that, taking needed shipments for companies around the world and transports them where they need to be, no matter when, where or what size.

What is CAP Logistics? What does it do as a company?

CAP Logistics is a multi-modal logistics company specializing in on-demand, customer driven transportation solutions. The company was started over 32 years ago to provide service to the heavy industries in remote locations in the Rocky Mountains that were trying to avoid expensive downtime.

Who are the primary players within the company?

We’re a smaller family-owned company, so while we have a traditional corporate hierarchy with “final say” decision makers, we tend to run more of a horizontal operation. This allows our management and executive leadership broad latitude to engage with our customers and our staff on a multitude of issues and opportunities. We’ve come to find out that through this team ideation process that we can identify answers and solutions quicker and more robust when we work as a collective team.

How was CAP Logistics created?

Like most entrepreneurial start-ups, CAP’s glamorous beginnings started in the basement of our owner’s, Gayle and Karen Dendinger’s house. Gayle delivered freight and made customer visits. Meanwhile, Karen had just delivered their first baby a year earlier so she stayed home taking shipments and handling all the accounting, but at the time, Karen knew nothing about freight so Gayle often jokes, ‘Karen used to answer the phone, take the order and as soon as she’d hang up her and the baby would both start crying.’ It was all worth it. The Dendinger’s opened their first office just a few short months later and the rest is well, history.

What makes it different from other companies of its type?

CAP Logistics is different on many levels. First and foremost, we’re a family company and not a big box forwarder. Because we operate with an emphasis on team ideation and groupthink, many of our employees share great camaraderie and respect along with pride in the service each person provides in varying roles throughout the company.

Just as important as our people, are our customers. CAP Logistics has spent the last 32 years focused on key heavy industries, creating specialized teams, while investing in technology and infrastructure to support these customers in remote and urban locations around the world. Through our proprietary business intelligence, we’ve customized profiles to accommodate special information for each individual customer and their unique needs and organizational standards.

We’ve also created the CAP Carrier Standard, which ensures our customers safe transportation of their freight. With ever changing regulations and standards CAP continues to be on the cusp of safety and risk management by only employing drivers and vendors with excellent driving records. This helps keep the public safe when drivers are on the road carrying our customer’s freight. It also means our customers will get all of their freight in tact!

Where are your headquarters and other offices?

CAP is headquartered in Denver, Colorado with operational locations in Chicago, Houston, Salt Lake City, and Southern California to serve heavy industries west of the Mississippi, although we do provide service throughout the East Coast and around the world.

Do you have facilities near bigger clients. What determines that? What is the primary purpose for that?

CAP Logistics has a broad customer base that encompasses various industries. Our national customer service staff and operational offices are located in areas that best serve our customers in key industries around the world. We’ve ultimately chosen these locations because of the industries we serve, not just for specific customers.

Give us examples of different types of projects. For example, I believe you are moving a large piece of equipment from one part of the world to Beulah, ND? Tell us about how you handle unique projects and tackle others that may not have been done before. Are there specific procedures you follow?

That’s correct, we just moved a large boiler for a coal to gasification plant to Beulah. The boiler this company needed was manufactured in Italy so it had to be trucked from Italy to Antwerp, Belgium. From there it sailed across the Atlantic, through the St. Lawrence Seaway and into the Great Lakes before arriving in Milwaukee where it was then trucked to Beulah. It took a lot of planning, paperwork and of course logistics, which our international team took in stride.

And of course, every shipment is different and every company has specific standards and requirements when you move their freight. Our international teams as well as our domestic teams have to take these requirements into account each and every time we get a shipment. End users change, supplier’s change and documentation can sometimes be very rigorous. It’s a lot to know if you don’t do it each and every day. So there really aren’t specific procedures to follow each time, because every shipment is like a puzzle with unique pieces and parts.

What might be the most unusual project that CAP Logistics has tackled?

We’ve had lots of unique moves over the years. Everything from taxidermy, generators, and computer chips, but some that really stand out are moving propane tanks through the Hawaiian Islands on a barge, chartering two Tomahawk helicopters to Asia, transferring oil-slicked turtles from a cleanup site to a wildlife refuge, and transporting a 118-foot long tractor-trailer rig carrying a generator rotor across the country on the Antanov 124, one of the largest aircraft in the world.

According to your Vice President of Sales & Marketing John Boner, CAP Logistics tackles jobs that others might not be able to tackle or perform. And thus, since they can be difficult, it is very important to be up front, honest and in good communication with the client. Tell us more about that? About client relations?

We always try to deliver realistic expectations to our customers at CAP Logistics. Most of our shipments are emergency or mission-critical so it’s very important that our customers are aware of their options. Most times we’ll have a customer call in and tell us what is going on, usually they have a specific idea of what they would like to do. Part of our process in creating unique customized solutions is by giving customers more ideas and options for their freight that they might not have considered. Most times, through conversations with our operations team, we can create new ways to transport their freight. And like anyone, people just want to be updated and communicated with. We want our customers to be aware of what is going on with their shipment. Because at the end of the day it’s the transparency in our work and the relationships that we build that means the most to our customers.

Tell us about your conscious as a company and how CAP Logistics contributes to the community because I know that it is very community conscious.

At CAP our team is our family and because of that the team collectively gets involved in endeavors and organizations that are near and dear to our “family”. CAP also participates in and gives to events and organizations that are in line with our business objectives. Gayle has always said, “It is good business to be a good neighbor.” That is always changing and evolving depending on what we are focused on or what is transpiring at a given moment. We always try to stay present with what is important to our employees and our customers, because at the end of the day, we wouldn’t be where we are without them.

This article originally appeared in The Drill, August 27, 2014

Unfortunately, the supplier dispatched the candy one day after the latest date allowed for shipment. When the issuing bank noted this discrepancy, they contacted the applicant for approval to pay, but the applicant declined because the late shipment meant missing the festival date. The Greek bank was notified that payment had been refused.

Unfortunately, the supplier dispatched the candy one day after the latest date allowed for shipment. When the issuing bank noted this discrepancy, they contacted the applicant for approval to pay, but the applicant declined because the late shipment meant missing the festival date. The Greek bank was notified that payment had been refused.

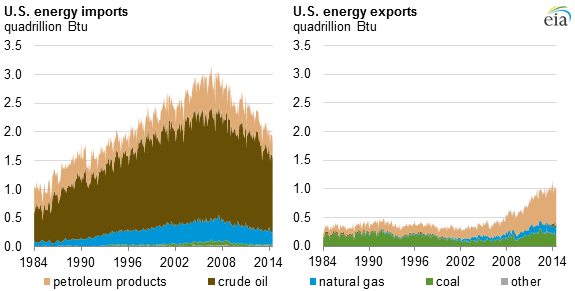

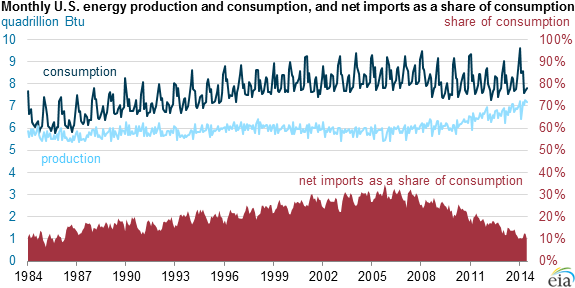

Total U.S. net imports of energy as a share of energy consumption fell to their lowest level in 29 years for the first six months of 2014. Total energy consumption in the first six months of 2014 was 3% above consumption during the first six months of 2013, but consumption growth was outpaced by increases in total energy production. These changes led to a 17% reduction in net imports compared with the first six months of 2013.

Total U.S. net imports of energy as a share of energy consumption fell to their lowest level in 29 years for the first six months of 2014. Total energy consumption in the first six months of 2014 was 3% above consumption during the first six months of 2013, but consumption growth was outpaced by increases in total energy production. These changes led to a 17% reduction in net imports compared with the first six months of 2013.