By: Kelly de la Torre Issue: Transformation Section: Business The Department of Defense (DoD), by executive order and legislative mandates, is required to reduce energy use, and transformational changes are under way to meet those mandates. Fortunately for the consumer, history shows that in times where the needs of the market align with defense priorities, we all benefit. Supported by strategic government investments, transformations have produced some of the greatest American success stories. Expansion of the railway system under President Abraham Lincoln led the industrialization of the West. A public-private partnership led to development of the first commercial nuclear reactor under President Eisenhower.

A key transformation occurred in the aeronautics industry under President Wilson. In 1915, President Wilson created the National Advisory Committee for Aeronautics (NACA), the predecessor to the National Aeronautics and Space Administration (NASA), in order to elevate America’s positioning in the aeronautics industry. In 1915, the United States was not competitive in its aviation capabilities and lagged behind Europe. With an initial appropriation of $5,000, NACA’s mission was to “direct and conduct research and experimentation in aeronautics, with a view to their practical solution.” Until World War II, research had both military and commercial applications. During the war, however, efforts were directed almost exclusively to the military, and the military’s ties with industry became much stronger. The result was the creation of the aerospace sector, and the effort showed that when the government puts its weight behind developing a sector or technologies, the potential benefits to our armed forces and our nation as a whole are huge.

We’re at a critical juncture. The size and scope of the energy challenges facing the United States are enormous, necessitating an efficient process to expedite deployment of new technologies. Under the leadership of Dr. Dorothy Robyn, deputy undersecretary of defense for Installations and Environment, the DoD created the Installation Energy Test Bed, a signal of DoD’s recognition that it can be a powerful catalyst for energy innovation. To get to market, however, emerging technology must move through the innovation pipeline comprising four critical phases: research, development, demonstration, and deployment. Each phase transition represents an opportunity for great achievement or a chance for failure. Especially critical is the transition from demonstration to deployment—often referred to as the valley of death. Testing of prototypes often requires large-scale complex development and manufacturing capabilities. To a large extent, DoD has these capabilities and extensive experience. For example, DoD pioneered and paved the way for commercial adoption of the jet engine, gas turbines, solid state electronics and the Internet, to name just a few technologies.

According to the July 2010 CNA report titled, Powering America’s Economy, the DoD has an established and robust research and development base for energy technology. The sheer size of DoD’s energy requirements (nearly 1 percent of all energy consumed in the United States, according to CNA) and the demonstrated need signal huge opportunity for the innovator; whereas the DoD has the large scale ability to demonstrate, test, fund and field new technology. Aligning the goals of these agencies would expedite deployment of new technologies. In 2010, the DoE and DoD entered into a Memorandum of Understanding defining the framework for cooperation and partnership between the agencies in order to maximize DoD access to DoE technical expertise and find solutions that meet DoD objectives.

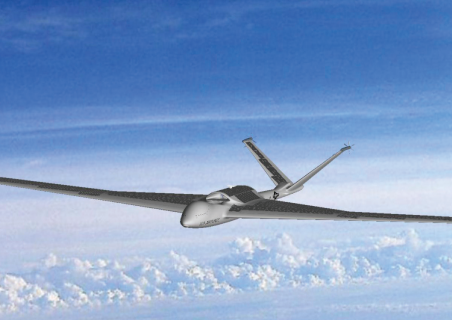

What DoD offers is an accelerated innovation cycle, and there are a number of companies poised to take advantage. For example, the development of a very-high-altitude solar-electric lighter-than-air unmanned aerial vehicle (UAV) platform is moving forward. Two Colorado companies, Global Near Space Services (GNSS) and Bye Aerospace, recently collaborated on design and research for the development of a unique solar-electric-powered airship named “Starlight.” The Starlight is a lighter-than-air UAV that uses solar electric energy stored in batteries to run propellers to keep the drone on a location. A special combination of technologies and design enable the drone to maintain station for four months at a time. Starlight is intended to be a high-altitude, long-endurance UAV system with military applications for border patrol, visual and thermal reconnaissance and forward air control. The civilian applications include traffic control, pipeline and power line inspection, aerial law enforcement, forest fire detection and aerial photography.

Aerospace projects such as Starlight are highly complex, requiring technology from a number of different sectors. A critical element is that the drone must be lightweight. This can be achieved by incorporating lightweight solar energy collectors and using advanced composite materials. "One concept currently in development—the Silent Guardian unmanned aerial vehicle—relies on thin-film solar photovoltaics, stored electric power and other technologies to enhance its potential for long endurance, quiet operations and low emissions," said George Bye, chair and chief executive officer of Bye Aerospace.

New developments in thin film solar photovoltaic (TFPV) technology have seen the conversion efficiency increase from 11 to 20 percent in research labs. This high conversion efficiency of sunlight energy to electric energy appears to allow for a meaningful supplement to some long-endurance flight aircraft. Ascent Solar Technologies, Inc. (Ascent), a developer of flexible CIGS solar panels, has been named a development partner for Bye Aerospace’s aircraft programs for the aerospace and defense markets. According to Victor Lee, president and CEO of Ascent, “Ascent Solar’s transformational technology enables renewable power generation in aircraft applications while adding minimal weight to the vehicle.” These lightweight flexible panels have a high power density to weight ratio and are a critical enabling technology to the Starlight and other UAVs being developed by Bye Aerospace.

Ascent’s panels employ CIGS photovoltaic technology on flexible, plastic substrate—a technology that has the potential to transform the way solar power can be used in everyday life. The technology was founded decades ago to enable aerospace and high-altitude applications because of its lightweight, flexible characteristics and its seamless integration with a number of substrates. As a company, Ascent plays on its strength and thinks differently than traditional solar organizations. Their business model is not to compete with glass crystalline modules but to look for any other surface to generate power. Because the panels integrate seamlessly with any number of substrates, the applications for the technology are limited only by imagination and access to the sun.

Panel features can vary by application. For example, for more robust applications, the panel can be attached to a thicker back-sheet and protected by a finish. The panels can be integrated into fabrics used in forward operating bases and as portable solar chargers for soldiers without weight burden. For example, Ascent is testing multi-kW scale tent flies designed to shade the tents and offset peak cooling times. Another application is foldable blankets designed as charging stations that can be quickly deployed and folded after use with minimal weight impact to the soldier’s backpack. These products have the capability of directly reducing the military's dependence on conventional fossil-fuel-based power systems, while simultaneously reducing the physical burden and security risk to soldiers. Ascent has already demonstrated commercial applicability as well in the electronics, building and transportation sectors.

Advances such as Ascent’s technology can also open a range of opportunities to address rural poverty reduction in underdeveloped parts of the world. The introduction of the cellphone has introduced opportunity to these areas. In some areas, however, people walk hours for access to diesel generators to charge their cellphone. Deployment of flexible solar charging stations provides an inexpensive and time-saving solution. These panels could further be applied to lanterns to replace those that are currently powered by kerosene.

With development of its technology, Ascent is helping power a transformation in our military and our commercial energy landscape. History shows that transformation has helped the United States remain globally competitive. It seems that if Ascent and Bye Aerospace are the models, the future is only limited by our imagination—and with the support of DoD, we can dream big.